In the past, many boats used a “dry” exhaust system, in which the exhaust gases were transported to outside the hull without any form of cooling. The resultant hot exhaust pipe had to be thoroughly insulated, but even so, it produced a tremendous amount of noise. However, reduction of exhaust gas temperature to about 40° or 50°C can be achieved by injecting the engine cooling water into the exhaust line. This is how a “wet” exhaust system works. In addition, the typical diesel exhaust smell is also considerably reduced. A further major advantage of reducing the temperature is the fact that all exhaust components downstream from the engine outlet can be made from rubber or synthetic materials. This permits greater design sophistication and weight reduction and ensures freedom from corrosion.

Why use a water-injected

“wet” exhaust system?

The following factors are of great importance:

- Exhaust gas temperatures can reach very high levels. A diesel engine can easily produce an exhaust gas temperature of 600°C or more.

- The speed with which sound can be transmitted through air is dependent on the temperature of the air. This applies to exhaust gases as well. The higher the exhaust temperature, the higher the speed of sound through the gas.

- The sound level, i.e. the relative volume of sound as experienced by the human ear, is in turn dependent on the speed of sound. As the speed of sound transmission reduces, so the sound level will reduce proportionally.

NLP Series

High Performance Exhaust

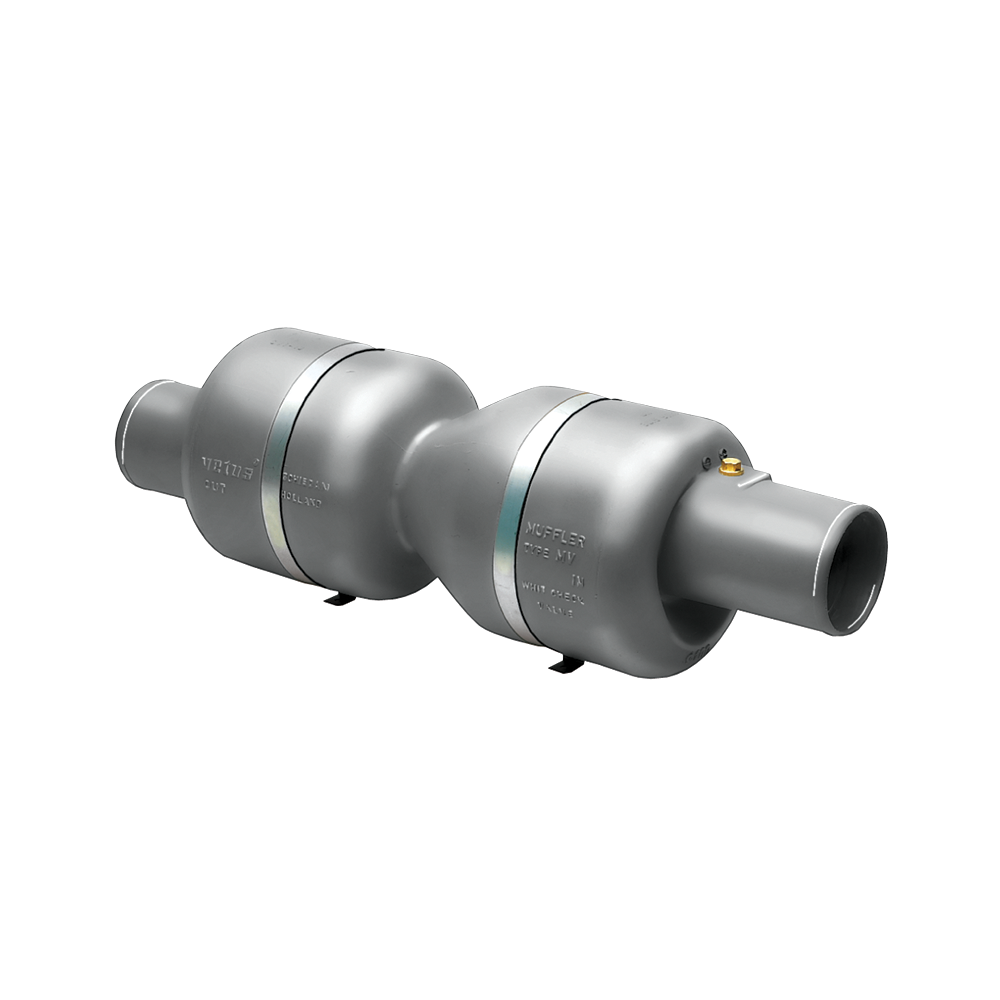

The NLP waterlocks are of dual stage construction, featuring upper and lower chambers with a horizontal partition plate and a riser tube through the centre. These NLP waterlocks offer superior silencing of exhaust noise with minimal back pressure. Since the top chamber may be rotated through 360° and both the inlet and the outlet connectors can rotate through 360°, installation of the exhaust assembly even in confined engine spaces is greatly simplified. The mounting brackets enable these waterlocks to be either bulkhead or floor mounted.

MG Series

MG series Waterlocks – Freedom in installation

Often in a modern high-performance boat, with one or two large engines installed, there is very little space to spare in the engine room. VETUS waterlocks, type MG are designed to make even the most awkward installation possible. The outlet connection at the top will rotate through 360° and the inlet connection is at an angle of 45° upward. For a minimum order quantity of 10 pieces, we can supply these waterlocks with the inlet or outlet connection at an angle of 0°, 15° or 30°. VETUS waterlocks, type MG, may only be installed in water injected exhaust systems. They are made entirely of synthetic materials (no corrosion or galvanic action), have excellent sound reduction properties, and cause minimal back pressure. The clamp bands are made of AISI 316 stainless steel. Provided with a drain plug. For exhaust of Ø 90 – Ø 250mm.

High Performance Exhaust

Exhaust systems for high-performance craft

These mufflers are specially developed for fast craft with powerful engines, where very often there is no space available for installation of a waterlock and/or gooseneck.

The waterlocks and the transom connection type TC are provided with a check valve (”flapper”), which ensures that under no circumstances (e.g. when in waves or manoeuvring astern) can the seawater flow towards the engine. Therefore, this system makes the installation of a gooseneck unnecessary.

LT Series

Goosenecks LT Series – Raising a barrier

A gooseneck which raises the exhaust hose above the waterline, so that water cannot backfill the exhaust system. After the engine is stopped, all cooling water in the exhaust hose will run to the lowest point of the system, which is where the waterlock should be situated. To limit the quantity of water, the gooseneck should be fitted as closely as possible behind the waterlock. But if required, it may also be fitted at the transom exhaust connection.

ASD Series air vents

Vacuum breaking anti-siphon air vents

If the point where the cooling water is injected into the exhaust is less than 15cm above the waterline, then when the engine is stopped, there is a risk that cooling water will siphon into the exhaust system and subsequently into the engine itself. Such siphoning may be prevented by fitting a VETUS ASD at least 40cm above the waterline.

XH Alarm

Exhaust temperature – the first indicator of cooling failure

A blockage in the engine water intake or a damaged pump impeller will result in complete loss, or severe reduction in the volume of cooling water in the exhaust system. In this case the temperature of the exhaust will rise much faster than the temperature of the engine. We recommend that a exhaust temperature alarm is always installed in the exhaust line as it is a relatively small investment that prevent serious damage to all parts of the exhaust system in the event that raw water flow stops or is significantly reduced.

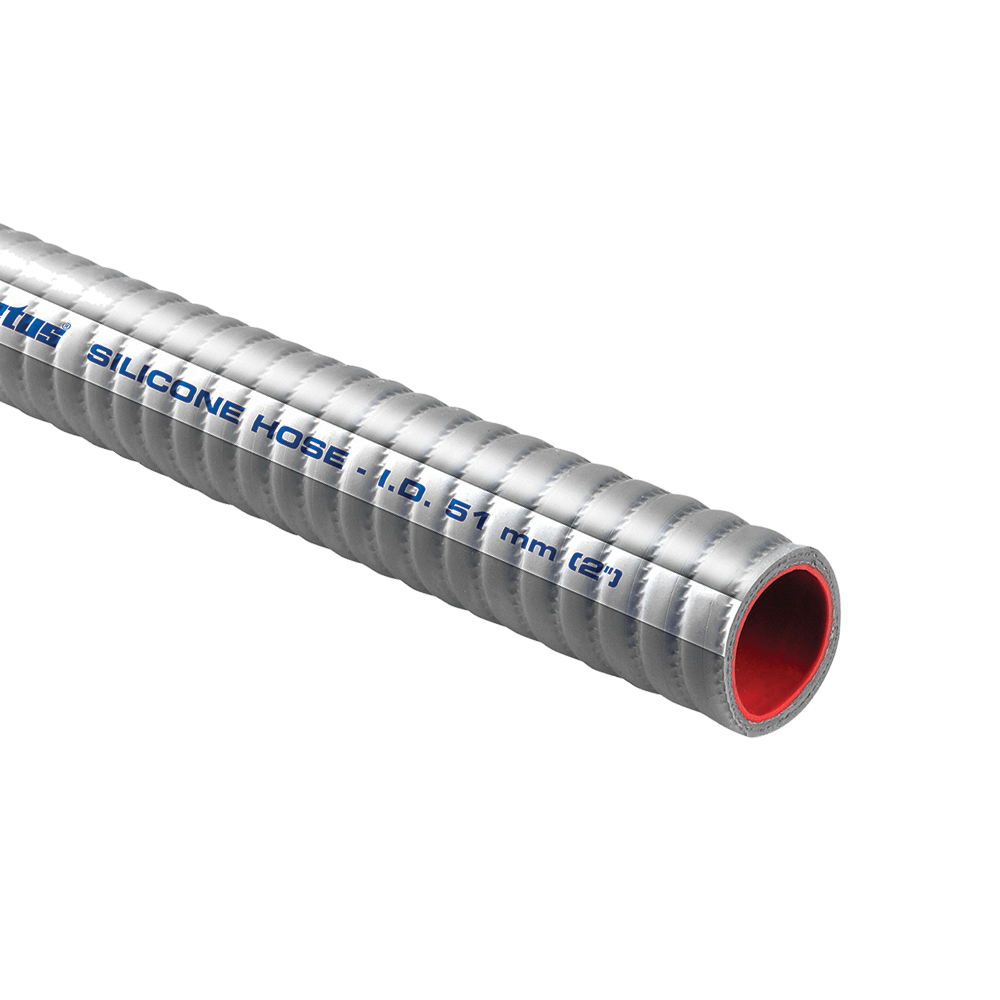

Exhaust hoses

Flexible and strong

Thanks to increased spiral reinforcement and a more supple type of rubber, VETUS exhaust hoses are now even stronger, as well as more flexible. Exhaust hoses with an internal diameter up to 152mm, have a bending radius of no more than 1.5 x the diameter. Exhaust hoses with an internal diameter of more than 152mm, have a bending radius of two times the diameter of the hose.